Pneumatic Die Lifters

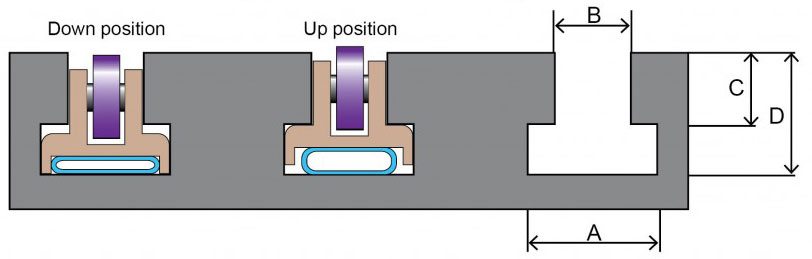

Green Valley Manufacturing has developed a standard line of Pneumatic Die lifters for stamping, and vertical molding presses. GVMI die lifters enable the tool to be elevated above the press bed surface on rollers for easy transfer to/from the press.

The pneumatic operation ensures a clean application without any of the oily mess associated with hydraulic units. The systems are economical and simple to install and operate.

Delivery time: 3-4 weeks.

BENEFITS

- Simple Installation

- No Oily Mess

- Economical

- Low Friction Die Transfers To/From Press

ORDERING INFORMATION & PRICING

Lift Capacity

| Part Number | Description | |

|---|---|---|

| 2PAB | 2-port manifold block | |

| 4PAB | 4-port manifold block | |

| 6PAB | 6-port manifold block | |

| 8PAB | 8-port manifold block | |

| 075 | die lifter for std. ¾” or 22mm t-slot * | |

| 100 | die lifter for std. 1” or 28mm t-slot * | |

| SS100 | slug shield option | |

| SS075 | slug shield option |

All manifolds come with 3/8” NPT female connector for shop air supply, one slide valve, and straight 1/4” tubing

push-lock connectors for air out to die lifters.

Each die lifter will contain a push-lock 90° elbow and 24” of 1/4” tubing to connect to manifold selected above.

* Include drawing with dimensions of your T-slot with your order.

Order

Your purchase order should list quantity and part number of the manifold(s), and quantity and length of each die lifter segment.

Note: Include detailed T-Slot dimensions for each press system.

Example: one pair of ¾” X 30” die lifters and one 2-port manifold block will be purchased as shown.

| Item | Part Number | Quantity | Description | ||

|---|---|---|---|---|---|

| 1 | 2PAB | 1 | 2-port manifold block | ||

| 2 | 075 | 2 | 30” die lifter for std. ¾” t-slot |